The Ocean Avenger PLUS Single Spindle carbide drill line is the ideal horizontal CNC multitasking machine that processes a wide variety of profiles including Beams, Angle, Channel, Plate, Flat Bar, T-Sections, Square or Rectangular Structural Tubing, Girders, Tapered Beams, Rails, Truck Frames, Rail Car Frames, and much more.

Whereas the original Avenger is limited to drilling and layout marking, the Avenger PLUS can do so much more. It features an 8 tool automatic tool changer that makes swift work in automating all types of machining processes including drilling, part marking, scribing layouts for welded attachments, milling of slots and machining surfaces, counter-boring and countersinking, flow drilling and so much more.

This vast array of processes and the variety of shapes it can process makes it suitable for all types of fabricators and we see this machine in all kinds of industries including structural, oil and gas, highway, rail and transport, billboard, manufacturing and even small job shops.

The Avenger PLUS accepts profiles up to 48” x 60ft (1250mm x 18m), and this allows you to process parts while other parts are being loaded or unloaded.

>> You might want to also consider the Avenger FORTY, Ocean Machinery’s smaller CNC Drill Line.

>> Click here to read about the Differences between the Avenger CNC Beam Drill Line and Avenger PLUS CNC Drill Line.

The Ocean Avenger PLUS is much more than an upgrade to the Ocean Avenger.

Whereas the standard Ocean Avenger still remains the most economical way to drill holes in long steel profiles, and layout marks for welded connections, the Ocean Avenger PLUS takes the single spindle concept to a whole new level. And none of the pretenders even come close.

Not only does the Avenger PLUS do everything that the Avenger does, it does so much more

— Drilling multiple columns of holes without having to unclamp and re-clamp

— Milling of horizontal and vertical slots, as well as milling of mechanical pass through’s. The maximum vertical slots are up to 46” or just shy of the maximum Y dimension of the part being processed, and the maximum X dimension is limited to the length of the machine (60ft) or the part being processed. Overlapping of multiple 6” slots can create a continuous slot. Milling of square holes to prevent carriage bolts from turning is simple to do on the Avenger PLUS.

— Milling a clean face onto a part – where surface finish or prep is required for mating parts

— Counter sinking – In certain industries, components require countersunk holes or beveled holes, and this is simple to do on the Avenger PLUS.

— Counter boring – In cases where the entire bolt head or nut has to be sunk, such as in the case of wear plates on crushers, hoppers, shot blasters and more, counter boring of holes is requires and this is simple to do with the Avenger

— Flow Drilling. Instead of having to do the difficult and time consuming process of welding a nut to the inside of a piece of RHS, consider using a flow drill to displace the material, and then thread the hole, providing a secure “nut” on the inside of the RHS.

The Ocean Avenger PLUS is designed specifically for fabricators and general job shops that need to do more than put holes in steel profiles of all types. Consider the following questions and determine if this machine fits your needs

If you answered YES to any of the questions above you are a prime candidate for the outstanding Ocean AvengerPLUS Beam Line, built by Peddinghaus USA.

Here are some of the more commonly asked questions

The Avenger PLUS uses CAT 40 tooling and we recommend tooling from Kennametal.

Photos

Videos

https://www.youtube.com/user/oceanmachinery

| Maximum Profile Height | 48″ | Based on max opening of primary material clamp |

| Maximum Profile Length | 60′ | Standard length of material support table is 66′ (Can be expanded) |

| Maximum X-Axis Speed | 150′ / Min | Maximum traverse speed of entire spindle carriage |

| Maximum Y-Axis Speed | 60′ / Min | Maximum speed of spindle motion |

| Spindle Motor Power | 25 HP | Servo spindle motor |

| Tool Changer Stations | 8 | Tools for threading, milling, countersinking, flow drilling, scribing and drilling holes of different diameter |

| Sub X-Axis Range of Motion | 5″ | Allows for scribing, milling, and tight hole patterns without the need to unclamp and re-clamp material |

| Spindle Speeds | 0 – 3000 RPM | Continuously Variable |

| Drilling Feed Rate | 0 – 30″ / min | Continuously variable |

| Vise Clamping Power | 0 – 30″ / min | Fully Adjustable |

| Power Supply | 460 Volt, 3 Phase, 60 Hz | Optional transformer available for other voltages |

“..One of our biggest headaches in the kitting department used to be the 15″ 50# channel. The parts in question are 26′ long and have 38 holes in them, 4 different diameters. We used to use templates that would at least layout the locations of the holes for us, but then it was a series of conveyors and a radial arm drill. We’d have to manually change out the drill bit 10 times and slide the 1300# part down the conveyor manually. It was, and still is a recurring job, we need 26 of these parts for each delivery, along with a couple other misc parts to make 13 complete kits. During the time of the radial arm drill the job was clocked at 60-90 minutes per 26′ stick, depending on who was doing it and how much ambition they had. Not only have we cut the time down dramatically but it’s also consistent. With the implementation of the Avenger Plus we’ve taken a 60 minute plus part and turned it into a 14 minute kit. Zero out of place holes, zero wrong size holes drilled, and best of all we’ve got capacity for any structural drilling and milling. Savings were passed on to the customer, and absorbed into our profit. As a side result, orders have increased in other areas from the customer, as well as the 15″ channel kits..”

Brad Cooper – Klein Steel Service – Rochester, NY

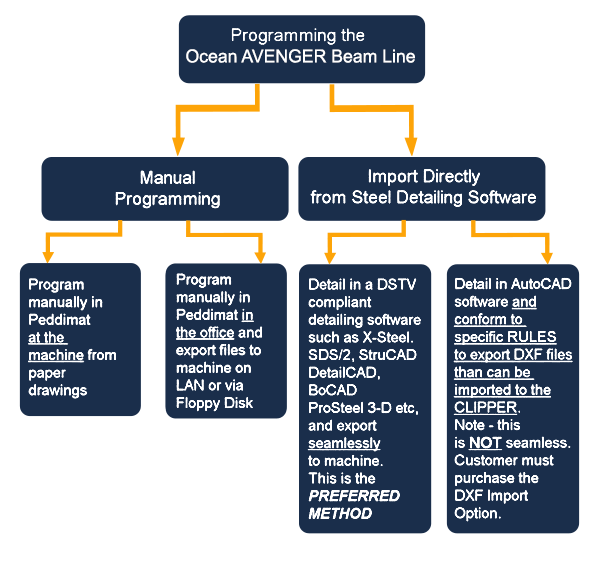

Programming the Ocean AvengerPLUS CNC Drill Line is very simple and intuitive even for operators with no CNC or computer experience.

We have installed more than a thousand CNC beam lines and angle lines throughout the world and we have found that the average operator, who has never before programmed a machine before, can become efficient on the machine in less than 1/2 day.

Ocean AVENGER CNC Beam Lines can be programmed in one of two ways:

1. At the machine, manually enter the profiles to be drilled.

2. Directly Import of the data to the CNC beam line directly from your CNC steel detailing files.

1. MANUALLY PROGRAMMING YOUR OCEAN AVENGER CNC BEAM DRILL LINE

A. MANUAL DETAILING (FROM A PAPER DRAWING)

The Ocean AVENGER can be programmed manually at the machine or in the office using the supplied Peddimat software. This software comes included with the AVENGER and can be installed on as many PCs in your office as you choose — this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the Ocean AVENGER and all Peddinghaus CNC fabricating machinery.

Peddimat is incredibly simple and intuitive, and takes less than an hour to learn, even if you have never worked on a computer in your life.

We always train your operator how to run the machine using Peddimat as you are often going to have the situation where a customer arrives with a couple of pieces of steel that need holes or layout marks and you want to be able to produce them quickly without bothering your detailing staff who might be busy on a larger job.

2. IMPORTING STEEL DETAILING FILES DIRECTLY TO YOUR OCEAN AVENGER CNC BEAM LINE

B. IMPORTING FILES DIRECTLY FROM YOUR STEEL DETAILING SOFTWARE

It is obviously preferable to import files directly from your steel detailing software because it eliminates an unnecessary step and also eliminates possible incorrect data capture. There are two separate and distinct camps in this respect:

1. 3-D Modeling Camp

Software that falls in this camp includes X-Steel, SDS/2, Tekla Structures, StruCAD, DetailCAD, BOCAD, SteelCAD, ProSteel 3-D etc. All these 3-D modeling programs export the DSTV file that is seamlessly imported into the AVENGER.

Your detailer will then supply you a DWG / PLT / PDF file that you will use to print or plot your drawings. He will also supply you with the NC or NC1 files that you will import directly into your machine. The DSTV-Import function is standard on the Ocean AVENGER.

2. AutoCAD Camp

AutoCAD is and architectural software and works well for exporting flat 2-D pieces to plate processing machines. Where it falls short is in its ability to export files for 3-D shapes like beams, channel, angles etc. AutoCAD exports both DWG files and DXF files which are perfect for plates.

The Ocean AVENGER can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

Once you have created a DXF IMPORT COMPLIANT AutoCAD file, you then import it via the DXF-Import Utility (optional purchase)

The Ocean AvengerPLUS CNC Drill Line is typically sold with the following options:

The Ocean Flipper Beam Rotator is a simple and unique material handling component, that was originally designed to fit within the material support tables of the Ocean Avenger and other single-spindle drill lines, or other types of steel processing equipment where turning and positioning of profiles is required.

The Flipper reduces the demand on the overhead cranes, leaving this valuable resource free to move other items while the Flipper rotates beams on the Avenger. >>MORE ABOUT THE FLIPPER

The Avenger PLUS uses standard CAT 40 tooling. With spindle speeds up to 3,000RPM it is important to use quality tooling to achieve the best results. Ocean and Peddinghaus recommend Kennametal Tooling. Ocean can handle all your tooling needs from drill bits (carbide, HSS and Cobalt), scribing (carbide), milling, threading, flow drilling and more.

Ocean offers two sizes of positioning magnets to assist with drilling base plates and flat bar. Magnets are available in 8×8″ (200x200mm) and 4×4″ (100x100mm)

These drop-in serrated grippers help to secure base plates, flat bar, angle and other profiles that might have rounded edges that want to push away from the datum line

The Ocean AvengerPLUS is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean AvengerPLUS. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

The Ocean AvengerPLUS is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean AvengerPLUS. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

Peddinghaus’s commitment to service and support is legendary and is the gold standard in the industry. Peddinghaus offers a global team of customer support representatives that are always available at the Peddinghaus 24 hour customer support center. Through state-of-the-art remote diagnostic software, readily available local field support, and the industry leading warranty, support from Peddinghaus is only a call or a click away.

To service our global clientele, Peddinghaus proudly provides our partners with 24 hour technical support. Peddinghaus’ inside service staff have years of experience in the field, assembly, or factory checkout which provides them with hands-on experience with most machines. At Peddinghaus their service staff is not only available when you need them, but they maintain superior knowledge to solve questions as they arise.

Although 90% of support issues can be resolved by Peddinghaus’ 24 Hour Tech Support center, an expansive network of 50+ Peddinghaus field service personnel are stationed throughout North and South America, Europe, Africa, Asia, Russia, the Middle East and Australia/New Zealand.

Peddinghaus inside service technicians often don’t need to be at your machine to solve a problem you may have. A common internet connection is all that is needed for the Peddinghaus technician to operate your control as if he was standing with you at the machine. The Powerful Windows® based Siemens control used on Peddinghaus equipment allows for this capability, and provides superior diagnostics via Windows® based platform.

Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Peddinghaus machines are shipped with high definition web cameras and software; allowing Peddinghaus employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.

The Peddinghaus Technical Support Office is open from 7am to 7pm Central Time, and is always ready to answer your questions, no matter how simple or complicated.

Call Peddinghaus Technical Service at (815) 937-3800

Toll Free (800) 786-2448

The office hours for Ocean Machinery are 8am to 5pm Eastern Time, and we are intimately familiar with all aspects of the machine and we welcome your technical support calls

Call Ocean Machinery Technical Service at (800) 286-3624