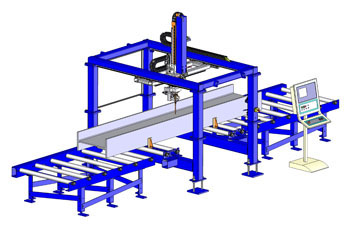

The Ocean Liberator CNC Beam Coping Machine is the most affordable beam coper in the world, and is the result of a strong and productive collaboration with Peddinghaus, the number one manufacturer of structural steel fabricating machinery.

The Ocean Liberator will cut the copes in your steel beams faster than your layout man can even layout the copes. – Check out our CNC Beam Coping Time Study Videos.

In the same way that the Ocean Avenger CNC Beam Drill Line and the Ocean Clipper CNC Angle Line brought affordable automation of beams and angles to the small-to-medium fabricator, the Ocean Liberator similarly brings automated beam coping into shops that otherwise could never have considered it.

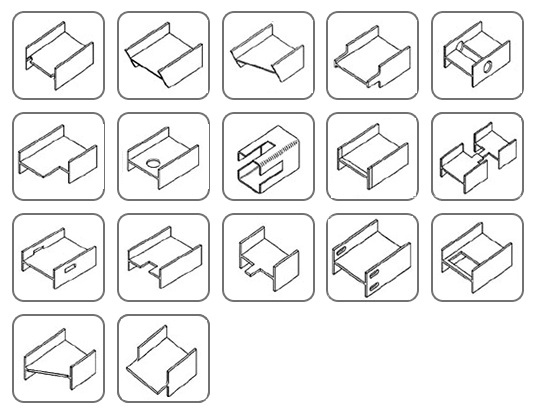

The Ocean Liberator is an amazingly economical 5-axis CNC robotic oxy-fuel cutting beam coper that will enable you to make any type of cut on beams, channels, angels, plates, and rectangular tubes.

Literally anything that you can draw, can be cut by this superbly versatile profile cutting machine. Not only does it cope, but it cuts to length too!

This single torch CNC beam coper removes the need for manually laying out your copes, and ensures that copes are done neatly and accurately, direct from your CNC detail drawings.

| Cutting Capabilities | |

| Maximum Profile Size | 44″ x 24″ (1100mm x 600mm) |

| Maximum Plate Width | 48″ (1250mm) |

| Flange Bevels | +/- 45 degrees |

| Web bevels | +/- 45 degrees (external only) |

| Maximum Material Thickness | 6″ (150mm) |

| Type of Cuts Programmed | All cuts are programmable |

| Travel Speeds | |

| Traverse Speed | 100 – 400 in/min (2.5 – 10m/min) |

| Cutting Speed | 7 – 30 in/min (170mm – 750mm/min) |

| Travel Dimensions | |

| “X”-axis (direction of flow) | 46″ (1168mm) |

| “Y”-axis (cross travel) | 76″ (1930mm) |

| “Z”-axis (vertical travel) | 30″ (762mm) |

| “B”-axis (bevel angle) | 270 degrees |

| “C”-axis (torch rotation) | 270 degrees |

| Accuracy | |

| Repeatability of X, Y & Z | +/- 0.001″ (0.025mm) |

| Cutting with Oxyfuel | +/- 0.0625″ (1.5mm) |

| Cutting kerfs depend on tip selection and heat adjustments | |

The Ocean LIBERATOR CNC Beam Coper is designed specifically for fabricators and general job shops that need to cope or notch steel profiles of all types. Consider the following questions and determine if this machine fits your needs:

If you answered YES to any of the questions above you are a prime candidate for the outstanding Ocean LIBERATOR Beam Coping Machine, built by Peddinghaus USA.

Here are some of the more commonly asked questions

We always recommend that your Ocean LIBERATOR CNC Beam Coping Machine operator is someone who really knows how to cut with oxy-fuel. We can train almost any operator very quickly on the software side of the machine, but the skill and experience of cutting with gas is something that is built up over years of cutting by hand.

The Ocean LIBERATOR CNC Beam Coper is very simple to operate and most of our LIBERATOR operators were the men doing layout on the floor. No prior computer knowledge is necessary, and full training is provided at the time of the installation.

Programming of the LIBERATOR is very simple even when done manually. The machine programming software is Peddimat and most operators can learn how to program most parts in less than an hour. Of course practice makes perfect. However the best way to program the machine is to import parts directly from a CAD drawing preferably done in some 3-D modeling software such as Tekla Structures, SDS/2, ProSteel 3D, StruMis etc. These files import directly into the machine. In some cases the operator might need to edit the part program to create a lead out to ensure smooth cutting and then he merely selects the part to be processed and hits the Cycle Start button.

Since the operator’s skills with cutting with gas are so important, we always prefer that your operator/s attend our LIBERATOR certification program at Peddinghaus’ in-house training center. This one week training course is provided free of charge when you purchase your LIBERATOR. Your operators will be fully trained and certified prior to the arrival of your new machine at your site.

At the time of machine installation our factory trained service tech will spend approximately 5 days on site, installing your machine, calibrating it and re-training your operators. This will provide more than enough hands on operation, as well as maintenance, troubleshooting and diagnostic training.

*NOTE: Coping machines, more than any other CNC machine in structural steel shops, depend on well-trained operators. It is your responsibility to ensure that all Ocean Liberator operators have been trained in our Operator Certification Program.

While we always prefer that the machine is installed indoors, we do in fact have several LIBERATOR beam coper installations outside. However suitable weather protection must be provided to the control panel and the machine itself. Please feel free to contact us to see photos from many of our outside installations.

Peddinghaus builds machines specifically for Ocean Machinery to meet our demanding specifications. Ocean Machinery specifically targets the small to medium fabricator whereas Peddinghaus targets the larger fabricators. Peddinghaus has been building machines for Ocean Machinery for more than 10 years, and Ocean Machinery is Peddinghaus largest customer worldwide.

The Ocean LIBERATOR is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean LIBERATOR. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise. Please see the SUPPORT tab for more answers relating to service.

The LIBERATOR beam coping machine is a very simple machine with very few moving parts, making maintenance and parts exceptionally affordable. The Ocean LIBERATOR was designed specifically to be used throughout the world and thus uses only components from major manufacturers, most of which can be sourced in the local market. Peddinghaus keeps all parts on hand for next day delivery in the USA. In most of our overseas countries we offer local service and support.

Plasma heads are very popular for cutting steel, due to the high quality and speed of the cuts. However, due to the size of the plasma cutting head it is not possible to get the head close enough to the flange, and many styles of copes typically required in beams are just not possible with plasma heads.

Another drawback is that when cutting thicker areas of a part, even on light wide-flange beams, for instance the radius at the intersection of the web and the flange, it is typical for the flame to blow back, and this can and cause damage to the plasma head.

Because the Ocean Liberator CNC Beam Coping Machine utilizes oxy-fuel, thickness of material is totally irrelevant and any material up to 6″ can be coped.

And of course the most important reason is cost. Cutting steel with plasma produces highly carcinogenic dust that MUST be captured in a dust extraction filtering system. This as well as the cost to completely enclose the machine to evacuate the dust raises the price to far beyond what our typical fabricator is prepared to pay for a beam coping solution.

The cutting head for the Ocean Liberator CNC Beam Coping Machine is a simple and inexpensive oxy-fuel head, and utilizes oxygen and any fuel of your choice, including propane, acetylene, propylene, or natural gas. These gases are very inexpensive and freely available from your welding supplier, and welders familiar with hand torch cutting will be able to set up the flow rates of the Oxy-Fuel just as they are used to doing.

The Ocean Liberator uses a specially designed torch nozzle that will typically last about 3 – 6 months depending on how hot you run the machine. Because of the break-away head that deflects the torch nozzle, the torch nozzle is almost impossible to bend.

However, the nozzles eventually get worn out due to the heat of the gases passing through the nozzle. Replacement torch tips are around $75 per tip.

A single torch CNC beam coping machine is a 5-axis machine that uses only one torch to do all the coping. When coping a beam, the single torch will start cutting at the web and then move on to the flanges. It moves from the web to each flange in sequence. The 5-axis torch is able to move in an almost infinite number of directions and positions, allowing the most complex of copes. The 5-axis torch and will accomplish double miter/bevel cuts on both flange and web – something that multi-torch systems are unable to do.

Multiple torch or triple torch CNC beam coping machines typically have three torches, and each torch is dedicated to a flange or web. Even though there is less positioning time with the triple torch machine than there is with the single torch machine, the single torch machine can do a lot more cuts than the EXISTING triple torch machines due to the versatility of the 5-axis movement of the cutting head. In addition, most triple torch machines cost 3-4 times more than our single torch CNC beam coping machine.

And most importantly, several large fabricators have upgraded from a 3-torch machine to an Ocean LIBERATOR. That will tell you everything!

Peddinghaus offers regular training courses on all Peddinghaus and Ocean equipment at their facility in Bradley Illinois. These courses are suitable for new operators and for refreshing existing operators. Employees that pass through this facility return to your shop highly trained, motivated and eager to improve your productivity. Please call for details and pricing.

The LIBERATOR is supplied with a 12 months parts and labor on-site warranty. If your Ocean Liberator Beam Coping Machine breaks down during the warranty period, factory service technicians will get your machine up and producing in the shortest amount of time possible, at no cost to you.

Outside the warranty period, on-site technical support is available at standard charge out rates.

Ocean Machinery and Peddinghaus are dedicated to proving affordable, reliable CNC solutions that not only work, but also provide safe operation for your employees. The Ocean Liberator is built to the highest safety standards using state of the art components.

Using a CNC beam coping machine is actually safer than using a handheld torch. The operator is able to operate the machine remotely and this moves the operator further removed from the cutting flame.

The Ocean Liberator beam coping machine is equipped with extended rigid and durable torch tips that enable accurate positioning inside flanges. In addition, the closed loop system allows the torch head to break away in the event that the torch head contacts an unexpected obstruction, such as slag build-up.

This safety mechanism ensures long tip and head life as well as significantly increasing up time to avoid costly torch tip changeovers and repairs.

All pressure and flow gauges for all gases are easily accessible and can be quickly adjustable.

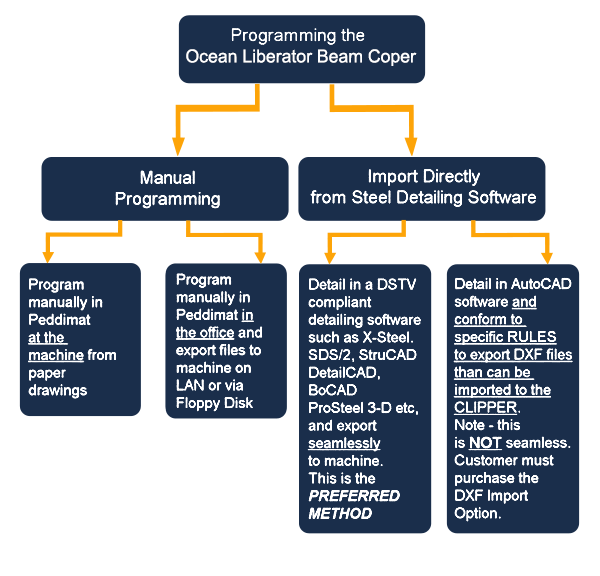

Programming the Ocean LIBERATOR CNC Beam Coping Machine is very simple and intuitive even for operators with no CNC or computer experience.

We have installed more than a thousand CNC beam lines and angle lines throughout the world and we have found that the average operator, who has never before programmed a machine before, can become efficient on the machine in less than 1/2 day.

Ocean LIBERATOR CNC Beam Coping Machines can be programmed in one of two ways:

1. At the machine, manually enter the clip angle data including the angle size, length, size and position of slots and holes.

2. Directly Import of the data to the CNC beam line directly from your CNC steel detailing files.

1. MANUALLY PROGRAMMING YOUR OCEAN LIBERATOR CNC BEAM COPING MACHINE

A. MANUAL DETAILING (FROM A PAPER DRAWING)

The Ocean LIBERATOR can be programmed manually at the machine or in the office using the supplied Peddimat software. This software comes included with the LIBERATOR and can be installed on as many PCs in your office as you choose — this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the Ocean LIBERATOR and all Peddinghaus CNC fabricating machinery.

Peddimat is incredibly simple and intuitive, and takes less than an hour to learn, even if you have never worked on a computer in your life.

We always train your operator how to run the machine using Peddimat as you are often going to have the situation where a customer arrives with a couple of pieces of steel that need holes or layout marks and you want to be able to produce them quickly without bothering your detailing staff who might be busy on a larger job.

2. IMPORTING STEEL DETAILING FILES DIRECTLY TO YOUR OCEAN LIBERATOR CNC Beam Coping Machine

B. IMPORTING FILES DIRECTLY FROM YOUR STEEL DETAILING SOFTWARE

It is obviously preferable to import files directly from your steel detailing software because it eliminates an unnecessary step and also eliminates possible incorrect data capture. There are two separate and distinct camps in this respect:

1. 3-D Modeling Camp

Software that falls in this camp includes X-Steel, SDS/2, Tekla Structures, StruCAD, DetailCAD, BOCAD, SteelCAD, ProSteel 3-D etc. All these 3-D modeling programs export the DSTV file that is seamlessly imported into the LIBERATOR.

Your detailer will then supply you a DWG / PLT / PDF file that you will use to print or plot your drawings. He will also supply you with the NC or NC1 files that you will import directly into your machine. The DSTV-Import function is standard on the Ocean LIBERATOR.

2. AutoCAD Camp

AutoCAD is and architectural software and works well for exporting flat 2-D pieces to plate processing machines. Where it falls short is in its ability to export files for 3-D shapes like beams, channel, angles etc. AutoCAD exports both DWG files and DXF files which are perfect for plates.

The Ocean LIBERATOR can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

Once you have created a DXF IMPORT COMPLIANT AutoCAD file, you then import it via the DXF-Import Utility (optional purchase)

The Ocean Avenger uses a special long torch nozzle to get close to the inside of Flanges. We supply these is variety of sizes depending on the thickness of material to be cut. Torches tips are also gas specific so please indicate what type of gas you are using:- Acetylene, Natural Gas, MAPP, Propane, Etc.

The Ocean Liberator requires roller conveyors to move the steel through the machine. Ocean Machinery supplies a modular system made specifically for the machine. This modular system is called the Ocean Eliminator and features in-feed and out-feed powered roller conveyors, as well as powered lift and carry cross transfers.

Please check our Eliminator Material Handling page for more information.

The Ocean Liberator is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Liberator. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

The Ocean Liberator is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Liberator. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

Peddinghaus’s commitment to service and support is legendary and is the gold standard in the industry. Peddinghaus offers a global team of customer support representatives that are always available at the Peddinghaus 24 hour customer support center. Through state-of-the-art remote diagnostic software, readily available local field support, and the industry leading warranty, support from Peddinghaus is only a call or a click away.

To service our global clientele, Peddinghaus proudly provides our partners with 24 hour technical support. Peddinghaus’ inside service staff have years of experience in the field, assembly, or factory checkout which provides them with hands-on experience with most machines. At Peddinghaus their service staff is not only available when you need them, but they maintain superior knowledge to solve questions as they arise.

Although 90% of support issues can be resolved by Peddinghaus’ 24 Hour Tech Support center, an expansive network of 50+ Peddinghaus field service personnel are stationed throughout North and South America, Europe, Africa, Asia, Russia, the Middle East and Australia/New Zealand.

Peddinghaus inside service technicians often don’t need to be at your machine to solve a problem you may have. A common internet connection is all that is needed for the Peddinghaus technician to operate your control as if he was standing with you at the machine. The Powerful Windows® based Siemens control used on Peddinghaus equipment allows for this capability, and provides superior diagnostics via Windows® based platform.

Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Peddinghaus machines are shipped with high definition web cameras and software; allowing Peddinghaus employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.

The Peddinghaus Technical Support Office is open 24 hours a day, and is always ready to answer your questions, no matter how simple or complicated.

Call Peddinghaus Technical Service at (815) 937-3800

Toll Free (800) 786-2448

Our office hours are 8am to 5pm Eastern Time. We are intimately familiar with all aspects of the machine and we welcome your technical support calls at any time during our business hours.

Call Ocean Machinery Technical Service at (800) 286-3624

“.. in the two and a half years we have had an Ocean Liberator, the efficiency and quality of the preparation procedures for our product has been drastically increased. Coping and weld prep of the past was very time consuming. Manually laying out and burning left a lot to be desired. With the Liberator, the burns are much cleaner, reducing grind time dramatically. The Liberator is a compact machine that delivers big results. All in all, Ocean has provided an opportunity to save time and energy, which equals out to saving money and our customers get a quality product.”

“..the time the Liberator saves us for cutting the beam itself, you add on top of that the time it saves us fitting 2 pieces together so accurately that no trimming or additional work is required. In regard to welding, we are not filling gaps anymore. We save time in both the fitting and welding of the structure. Beyond that the amount of grey hair I have saved from having the Liberator do my work, as far as I am concerned is PRICELESS!”