The Ocean Clipper II CNC Angle Line is not only the world’s most affordable angle line, it is also the world’s most compact angle line.

The unique patented design of the Ocean CLIPPER II gives it an edge in the marketplace where processing clip angles and long bracing angles is a necessity. And the ability of the Clipper II to efficiently process short and long flat bar makes this machine so versatile.

The angle processing range is from 1-1/2” x 1-1/2 x 1/8” (40 x 40 x 4mm) up to 6 x 6 x 5/8” (150 x 150 x 15mm), in any length, and for flat bar the range is from 2 x1/4” (50 x 6mm) up to 6 x 5/8” (150 x 15mm).

The CLIPPER II uses a unique design featuring two punch units with removable C-frame tool holders, creating a dramatically more compact machine that is more user-friendly. This small compact size not only reduces the cost significantly, it also reduces the remnant to approximately 9″ (230mm).

The small footprint required and the low cost of the machine have resulted in the Ocean CLIPPER II Series being the fastest selling angle line in the world, and has made it possible for even the smallest fabricators to have their own automated angle production. Our smallest CLIPPER II angle line customers have fewer than five shop floor employees.

Most fabricators who have angle lines will tell you that they seldom run their angle lines all day – they normally run in short bursts producing enough clip angles to provide the fitters clips to last the shift or possibly several shifts.

Despite only running a few hours a day, CNC angle lines still make great economic sense – producing perfectly accurate clips and other parts in the fastest possible time, eliminating huge amounts of expensive man hours, and eliminating errors. These parts fit up faster due to their accuracy and the fabricator never has to wait for deliveries from outside.

With the knowledge that the average fabricator would only run his angle line a few hours a day, Ocean Machinery and Peddinghaus decided to design and produce a completely unique machine that would do it faster and cheaper than any others on the market, and at last make angle lines affordable for the small to medium fabricator.

We closely studied the clip angle market in the USA and the rest of the world, and realized there was an opportunity for a machine that was more compact and more affordable than the current offerings.

To achieve our design approach, we needed to reduce the overall size of the typical angle line. In doing so we would also help to reduce the cost of the machine as well.

Despite its compact size, the Ocean CLIPPER II CNC Angle Line is designed for heavy duty work in the toughest fabricating shops in the world. It uses many of the same components found on other Peddinghaus angle lines.

The 75 Ton Hydraulic Punch is One of Peddinghaus’s standard heavy-duty units and its punching cycle is less than 2 seconds.

It has a maximum hole size of 1-1/4″ (Standard No. 270 punches).

Standard inexpensive punches and dies are available from Ocean Machinery and other vendors.

The robust 100 Ton Double Cut Shear has a cycle time of only 5 seconds and shears steel to 5/8″ thick, with a drop of only 1/2″.

With the Ocean Clipper, Peddinghaus and Ocean Machinery have succeeded in creating a powerful yet compact clip angle processing machine that eliminates another costly labor area in steel fabricating.

| Angle Sizes | |

| Max. Angle Size | 6 x 6 x 5/8″ (150 x 150 x 15mm) |

| Min. Angle Size | 1-1/2 x 1-1/2 x 1/8″ (40 x 40 x 4mm) |

| Flat Bar Sizes | |

| Max. Flat Bar Size | 6 x 5/8″ (150 x 15mm) |

| Min Flat Bar Size | 2 x 1/4″ (50 x 6mm) |

| Punch – Slots, Holes, Shapes etc. | |

| Punching Tonnage | 75 Tons US (68 Metric Tons) |

| Max. Punch Size | 1-1/4″ Diameter – Standard (270)

26mm Diameter – Metric (PFP #3) |

| Punch Cycle Time | 2 seconds |

| Min. Gauges (Using 272 punches, 271 dies) | 11/16″ plus leg thickness for 1 1/2″ x 1 1/2″ through 2″ x 2″ angle

1 3/16″ plus leg thickness for 2 1/2″ x 2 1/2″ angle 1 1/4″ plus leg thickness for 3″ through 6″ angle sizes |

| Min. Gauges (Using PFP#3 punches and dies) | 15mm (.59″) plus leg thickness for 40mm x 40mm (1 1/2″ x 1 1/2″) through 50mm x 50mm (2″ x 2″) angle sizes

24mm (.94″) plus leg thickness for anything over 50mm x 50mm (2″ x 2″) through 150mm x 150mm (6″ x 6″) angle sizes. |

| Shear – Cut to Length | |

| Shear Tonnage | 100 Tons US (91 Metric Tons) |

| Min. Remnant | 9″ (230mm) |

| Shear Cycle Time | 5 seconds |

| Slug Size | 1/2″ (12.7mm) |

| Measurement | |

| In-Feed Speed (X Axis) | 61 FPM (18.5 meters/min.) max. |

| General | |

| Machine Pass Line | 45″ (1143mm) |

| Weight | Main Assembly with Consolet – 8,500 lbs (3,860 kg)

Crate with Safety Stands & Transformer – 930 lbs (420 kg) |

| Power Requirements | 480V-60 Hz or 400V-50 Hz |

| Shop Air | 90 PSIG, 10 SCFM for machines with Unist option 90 PSIG, 50 SCFM for machines with Signoscript option None for machines without above options |

| Foundation | 6″ (100mm) concrete |

The Ocean Clipper II CNC Angle Line is designed specifically for fabricators and general fab shops that need to punch holes in angles and bars and shear it to length. Consider the following questions and determine if this machine fits your needs

If you answered YES to any of the questions above then the Ocean Clipper II CNC Angle Line was specifically designed for you.

This American made clip angle processing machine has been especially designed for the structural steel fabricator to eliminate costly manual layout and punching procedures. By expediting processing times through elimination of human labor, fabricators achieve greater profits while greatly increasing their tonnage-per-month and tonnage-per-employee outputs.

The Ocean CLIPPER II CNC Angle Line can be installed in any structural steel fabrication shop or other operation where layout and punching of clip angles or similar parts is required. It is capable of processing angles from as small as 1-1/2″ x 1-1/2″ x 1/8″ all the way up to 6″ x 6″ x 5/8″ (32x32x3mm up to 150x150x16mm).

Here are some of the more commonly asked questions

The Clipper II CNC Angle Line is very simple to operate and most of our Clipper operators were the men doing manual layout on the floor. No prior computer knowledge is necessary, and full training is provided at the time of the installation

Programming of the Clipper II Angle Line is very simple even when done manually. The machine programming software is Peddimat and most operators can learn how to program most parts in less than an hour. Of course practice makes perfect. However the best way to program the machine is to import parts directly from a CAD drawing preferably done in some 3-D modeling software such as Tekla Structures, SDS/2, ProSteel 3D, StruMIS, etc. These files import directly into the machine and the operator merely selects the part to be processed and hits the Cycle Start button.

The Ocean Clipper II can be installed and operational in your facility less than 5 days after receiving the machine. The machine is simple to install and most of the work is done by the customer prior to the service technician arriving at the customer’s facility.

We walk you through all aspects pre-installation. You will need to supply the following

At the time of machine installation our factory trained service tech will spend approximately 4 days on site, installing your machine, calibrating it and training your operators. This will provide more than enough hands on operation, as well as maintenance, troubleshooting and diagnostic training.

Yes. We have several Ocean Clipper II Angle Lines installed outside. However suitable weather protection must be provided to the machine and control panel, but the in-feed and out-feed conveyors can be exposed to the elements. Please feel free to contact us to see photos from many of our outside installations.

Peddinghaus builds machines specifically for Ocean Machinery to meet our demanding specifications. Ocean Machinery specifically targets the small to medium fabricator whereas Peddinghaus targets the larger fabricators. Peddinghaus has been building machines for Ocean Machinery for more than 10 years, and Ocean Machinery is Peddinghaus largest customer worldwide.

The Ocean Clipper II is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Clipper. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise. Please see the SUPPORT tab for more answers relating to service.

The Clipper II design makes maintenance and parts exceptionally affordable. The Ocean CLIPPER was designed specifically to be used throughout the world and thus uses only components from major manufacturers, most of which can be sourced in the local market. Peddinghaus keeps all parts on hand for next day delivery in the USA. In most of our overseas countries we offer local service and support.

When the Peddinghaus service technician has finished installing and calibrating your machine he will spend time with your operators taking them through our simple yet thorough training program. Your operators will receive training in:

– machine setup and adjustment

– machine maintenance and lubrication

– fault finding and troubleshooting

– programming of parts

– importing of parts

– how to change punches and dies

Peddinghaus offers regular training courses on all Peddinghaus and Ocean equipment at their facility in Bradley Illinois. These courses are suitable for new operators and for refreshing existing operators. Employees that pass through this facility return to your shop highly trained, motivated and eager to improve your productivity. Please call for details and pricing.

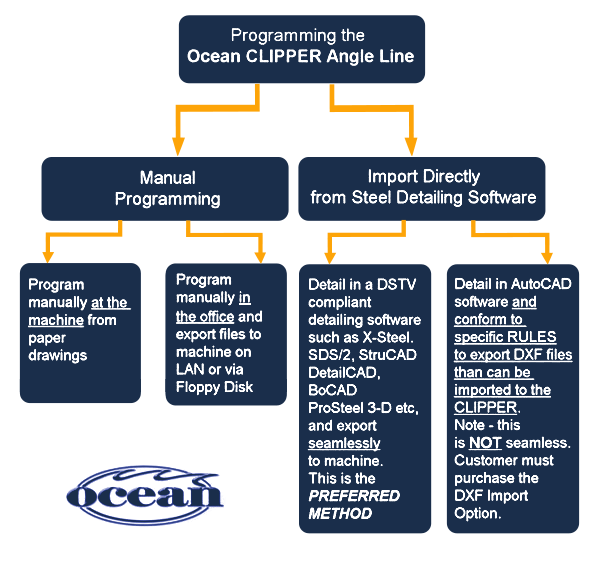

Programming the Ocean CLIPPER II CNC Angle line is very simple and intuitive even for operators with no CNC or computer experience.

We have installed more than a thousand CNC beam lines and angle lines throughout the world and we have found that the average operator, who has never before programmed a machine before, can become efficient on the machine in less than 1/2 day.

Ocean CLIPPER II CNC Angle Line can be programmed in one of two ways:

1. At the machine, manually enter the clip angle data including the angle size, length, size and position of slots and holes,

2. Directly Import of the data to the CNC angle line directly from your CNC steel detailing files

The Ocean CLIPPER II can be programmed manually at the machine or in the office using the supplied software. This software comes included with the CLIPPER II and can be installed on as many PC’s in your office as you choose – this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the Ocean CLIPPER II and all Peddinghaus CNC fabricating machinery.

The programming software is incredibly simple and intuitive, and takes less than an hour to learn, even if you have never worked on a computer in your life.

We always train your operator how to program the machine manually as you are often going to have the situation where a customer arrives with a couple of pieces of steel that need holes or layout marks and you want to be able to produce them quickly without bothering your detailing staff who might be busy on a larger job.

It is obviously preferable to import files directly from your steel detailing software because it eliminates an unnecessary step and also eliminates possible incorrect data capture. There are two separate and distinct camps in this respect

Software that falls in this camp includes X-Steel, SDS/2, Tekla Structures, StruCAD, DetailCAD, BOCAD, SteelCAD, ProSteel 3-D etc. All these 3-D modeling programs export the DSTV file that is seamlessly imported into the Clipper II CNC Angle Line.

Your detailer will then supply you a DWG / PLT / PDF file that you will use to print or plot your drawings. He will also supply you with the NC or NC1 files that you will import directly into your machine. The DSTV-Import function is standard on the Ocean CLIPPER II.

AutoCAD is and architectural software and works well for exporting flat 2-D pieces to plate processing machines. Where it falls short is in its ability to export files for 3-D shapes like beams, channel, angles etc. AutoCAD exports both DWG files and DXF files which are perfect for plates.

The Ocean CLIPPER II can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

Once you have created a DXF IMPORT COMPLIANT AutoCAD file, you then import it via the DXF-Import Utility (optional purchase)

The Ocean Clipper CNC Angle Line is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Clipper. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

Peddinghaus’s commitment to service and support is legendary and is the gold standard in the industry. Peddinghaus offers a global team of customer support representatives that are always available at the Peddinghaus 24 hour customer support center. Through state-of-the-art remote diagnostic software, readily available local field support, and the industry leading warranty, support from Peddinghaus is only a call or a click away.

To service our global clientele, Peddinghaus proudly provides our partners with 24 hour technical support. Peddinghaus’ inside service staff have years of experience in the field, assembly, or factory checkout which provides them with hands-on experience with most machines. At Peddinghaus their service staff is not only available when you need them, but they maintain superior knowledge to solve questions as they arise.

Although 90% of support issues can be resolved by Peddinghaus’ 24 Hour Tech Support center, an expansive network of 50+ Peddinghaus field service personnel are stationed throughout North and South America, Europe, Africa, Asia, Russia, the Middle East and Australia/New Zealand.

Peddinghaus inside service technicians often don’t need to be at your machine to solve a problem you may have. A common internet connection is all that is needed for the Peddinghaus technician to operate your control as if he was standing with you at the machine. The Powerful Windows® based Siemens control used on Peddinghaus equipment allows for this capability, and provides superior diagnostics via Windows® based platform.

Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Peddinghaus machines are shipped with high definition web cameras and software; allowing Peddinghaus employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.

The Peddinghaus Technical Support Office is open 24 hours a day, and is always ready to answer your questions, no matter how simple or complicated.Call Peddinghaus Technical Service at (815) 937-3800

Toll Free (800) 786-2448

Our office hours are 8am to 5pm Eastern Time. We are intimately familiar with all aspects of the machine and we welcome your technical support calls at any time during our business hours.

Call Ocean Machinery Technical Service at (800) 286-3624

“..The Ocean CLIPPER Clipper exceeded our expectations by enabling a low-maintenance, computer operated environment which has increased our productivity and decreased our production time by up to 60%. This machine keeps us exceeding customer demands and quality benchmarks while controlling costs … ultimately making us more nimble and successful in an overly competitive market..”

“..Atlas Welding has been using the Ocean Avenger Drill Line for about 2 years and our production efficiency has never been better. We’ve cut the time and cost for manpower and errors. Adding the Ocean Clipper angle master has made life even easier, having both machines cuts down a lot of costs, especially for large projects. The investment we have made will never be regretted. Thank you Ocean Machinery!..”