|

Magnetic base drills, also known as mag drills or slugger drills, are used to drill heavy steel sections where a handheld drill would not suffice. The base of the drill features an electromagnet, that when energized, locks the base of the drill to the steel profile and allows the operator to apply a steady drill feed rate without dislodging or moving the base. These drills vary in size, weight and their horsepower, thereby affecting the hole diameter they can drill. They are mostly used in structural steel but are also used in applications such as drilling truck frame rails, steel signage, guard rails, etc.

SHOP MAG DRILLS NOW |

|

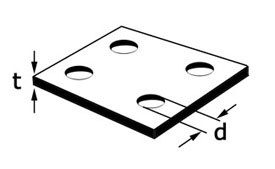

Mag drills normally use annular cutters as opposed to solid drill bits. These are hollow cutters, so only the outer perimeter of the drill is in contact with the steel, thereby significantly reducing the horsepower needed to drill a given diameter. |

|

Questions To Ask Yourself When Selecting A Mag DrillWhat is the maximum diameter hole that you need to make?

What is the depth of cut (D.O.C.) that you require? In other words; what is the thickness of the metal you need to drill? |

Some dual speed mag drills are designed to use both; HSS and Carbide tipped annular cutters.

The load sensing system in these auto-feed mag drills provides for faster cutting times; automatically adjusting the feed rate, and providing longer cutter life while eliminating the stress on motor due to improper operator pressure.

The versatility of some mag drills may be expanded with the use of optional accessories, such as:

|

Twist Drill AdapterAllowing the operator to use jobber drills from 1/2″ diameter and smaller with mag drills. |

|

Countersink KitThese kits allow the operator to quickly and easily counter sink for flat head bolts. |

|

Tapping AttachmentAs the name implies, this device is geared to tap steel. If your production requires tapping, make sure the mag drill you select will tap the size you need. Not all mag drills can reach up to 1-1/8; however, most can tap up to 3/4″. |

|

Chain MountThis accessory allows the operator to mount the mag drill on pipe and drill holes on center. The minimum pipe diameter is usually 3 & maximum is 12 ; larger sizes may be available based on the manufacturer. |

|

Mag Drill Vac PadsAllows the mag drill to be attached to non-ferrous metals with the use of shop air. |

|

Cutting Lubricant For Mag DrillsThe use of cutting fluid or cutting paste will extend the life of the annular cutter. |