The Ocean Avenger has been an immediate hit with the small to medium fabricator fabricating both structural steel and miscellaneous metals. Since it was introduced in 2003 more than 600 Ocean Avengers have been installed around the world, and this amazing machine has changed the lives of many a steel fabricator.

The Ocean Avenger Beam Drill Line is an extremely space efficient beam processing solution as it only requires a floor space of 70ft x 9ft, making it ideal for even the smallest fabricator or fabricators with space limitations. We also have many Avenger installations that are outside, freeing up even more space for the fabricator.

The Ocean Avenger not only lays out and drills all your holes in any steel profile in a fraction of the time it takes you to do it manually with a mag drill, but it also lays out the marks for all your welded attachments, virtually eliminating the need for a tape measure.

The Avenger is the most affordable CNC drill line on the market today and ensures that the fabricators is the low cost producer, allowing him to win more work and to make more margin.

Not only will the Avenger process beams and columns, but it also easily process all steel profiles including channel, angle, flat bar, base plates, RHS, square and round profiles.

>> You might want to also consider the Avenger PLUS, Ocean Machinery’s beast of a Multifunction CNC Drill Line.

>> Click here to read about the Differences between the Avenger CNC Beam Drill Line and Avenger PLUS CNC Drill Line.

The Ocean Avenger is designed specifically for fabricators and general job shops that need to put holes in steel profiles of all types. Consider the following questions and determine if this machine fits your needs.

If you answered YES to any of the questions above you are a prime candidate for the outstanding Ocean Avenger Beam Line, built by Peddinghaus USA.

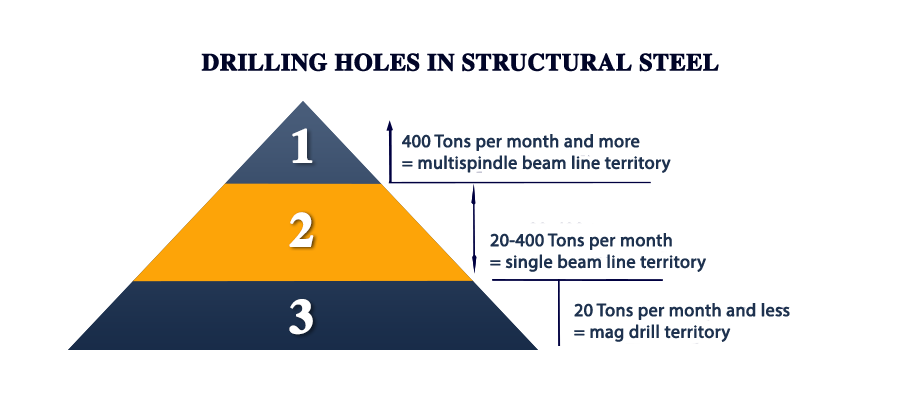

Now lets take a close look at the picture of the Beam Fabricating Industry below and see where you fit in.

Here are some of the more commonly asked questions

The Avenger is very simple to operate and most of our Avenger operators were the men doing layout on the floor. No prior computer knowledge is necessary, and full training is provided at the time of the installation

Programming of the Avenger is very simple even when done manually. The machine programing software is Peddimat and most operators can learn how to program most parts in less than an hour. Of course practice makes perfect. However the best way to program the machine is to import parts directly from a CAD drawing preferably done in some 3-D modeling software such as Tekla Structures, SDS/2, ProSteel 3D, StruMis etc. These files import directly into the machine and the operator merely selects the part to be processed and hits the Cycle Start button.

At the time of machine installation our factory trained service tech will spend approximately 8 days on site, installing your machine, calibrating it and training your operators. This will provide more than enough hands on operation, as well as maintenance, troubleshooting and diagnostic training.

Yes. We have many Avenger drill line installations outside. However suitable weather protection must be provided to the control panel and moving mobile platform. Please feel free to contact us to see photos from many of our outside installations.

Peddinghaus builds machines specifically for Ocean Machinery to meet our demanding specifications. Ocean Machinery specifically targets the small to medium fabricator whereas Peddinghaus targets the larger fabricators. Peddinghaus has been building machines for Ocean Machinery for more than 10 years, and Ocean Machinery is Peddinghaus largest customer worldwide.

The Ocean Avenger is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Avenger. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise. Please see the SUPPORT tab for more answers relating to service.

The Avenger is a 100% hydraulic machine making maintenance and parts exceptionally affordable. The Ocean Avenger was designed specifically to be used throughout the world and thus uses only components from major manufacturers, most of which can be sourced in the local market. Peddinghaus keeps all parts on hand for next day delivery in the USA. In most of our overseas countries we offer local service and support.

When the Peddinghaus service technician has finished installing and calibrating your machine he will spend time with your operators taking them through our simple yet thorough training program. Your operators will receive training in:

Peddinghaus offers regular training courses on all Peddinghaus and Ocean equipment at their facility in Bradley Illinois. These courses are suitable for new operators and for refreshing existing operators. Employees that pass through this facility return to your shop highly trained, motivated and eager to improve your productivity. Please call for details and pricing.

Brochures

Photos

Videos https://www.youtube.com/user/oceanmachinery

| Maximum Beam Size | Avenger FORTY accept profiles up to 40″ (1000mm) Avenger thirty accepts profiles up to 30″ (760mm). Max beam profile length 60ft (18.3m). Max profile weight 730 lbs/ft (1088kg/m) |

| Minimum Drill Diameter | 1/4″ (6.5mm) |

| Maximum Drill Diameter | 2″ (50mm) |

| Maximum Material Thickness | Up to 10″ (250mm) |

| Max Speed X Axis | 120 ft per minute |

| Max Speed Y Axis | 120 ft per minute |

| Spindle Motor Power | 13 3/4 hp |

| Drilling Speeds | 0-545 rpm (continuously variable) |

| Drilling Feed Rate | 2” – 10” per min (50-254mm) infinitely variable |

| Spindle Stroke | 13″ (330mm) Max. |

| Total Power | 20 HP (14.9 kW) |

| Power Supply | 208 to 575V, 3-ph, 60 Hz (50Hz available) |

| Average Output | 200 to 400 holes per hour depending on the profile drilled |

| Manufacturer | Peddinghaus Corporation, USA |

“.. In an effort to meet customer demands and increase production, we have installed a new beam drill line (Ocean Avenger), new saw (Ocean Terminator) and currently have on order your sand blast booth (Ocean Blaster). These processes not only speed up production; the resulting reduced labor cost and quicker turnaround times have consistently helped us in landing quality jobs.

I truly believe that without the support provided by the staff and personnel at Ocean Machinery we would not be performing in the steel fabrication markets that we now enviably find ourselves competing in..”

Ray Assmar – Pilot Steel – Owensboro, KY

“..since purchasing our Ocean Avenger about four months ago, we have drilled approximately 25,000 holes. It used to take us approximately 5 minutes to lay out and drill each hole. Now it takes us approx. 30 seconds per hole … a savings of 1875 man hours in 4 months. In our shop that equals about $84,375! As you can see this machine will pay for itself in less than one year. Not only is it speeding up our production, it is freeing up floor space for additional jobs..”

Charlie Mueller – SteelFab – Jackson, TN

“.. Although this machine is marketed for the Structural fabricators, I knew immediately it would work well for drilling truck frames. The accuracy & repeatability have ensured the assembly without error. The Avenger drills a set of channels for one truck in less than one 2 hours; when we did this manually, it would take 16 hours. This machine has increased our productivity & profitability hands down!..”

Mike Green – Engine And Accessories – Miami, FL

“..We purchased our first piece of CNC automated equipment from Ocean Machinery in 2002, an automated drill line, and the service and support during and after the sales process was top notch. When the Italian manufacturer was having trouble supporting our machine, Ocean Machinery stepped in to make sure we were up and running as quickly as possible.

So when it came time to add an additional drill line to our facility in 2007, we made sure Ocean Machinery was our first, and only, call. Their input during and after the sales process, combined with the superior knowledge of their support staff and the relationship their firm has with key manufacturers meant that we were up and running in no time and any problems that we have experienced were handled in a timely fashion. Ocean Machinery is a great partner to have on your side..”

Charlie Pfeil and Matt Tucker – Affton Fabricating – Sauget, IL

“..We were the first to get the Ocean Avenger in South Africa, and it completely changed our process. We had a few large jobs waiting and the Avenger paid for itself on those first three jobs. We have tripled our monthly tonnage and at the same time we have been able to lower our total labor headcount.

The versatility of the Avenger is amazing. We have done everything from simple steel structures, to high rise buildings, to countersunk floor plates — in fact the entire paint and assembly floor of the new Volkswagen factory in Port Elizabeth was done with the Ocean Avenger. This machine does everything they said it would, and more!..”

Ginkel Venter – Uitenhage Super Steel – Port Elizabeth, South Africa

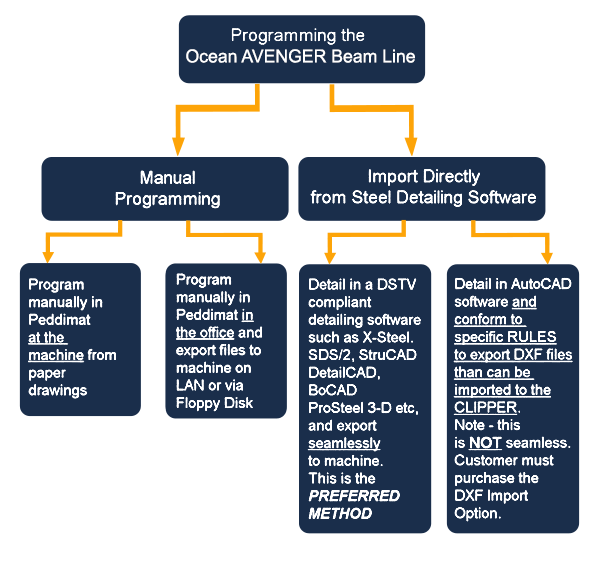

Programming the Ocean AVENGER CNC Beam line is very simple and intuitive even for operators with no CNC or computer experience.

We have installed more than a thousand CNC beam lines and angle lines throughout the world and we have found that the average operator, who has never before programmed a machine before, can become efficient on the machine in less than 1/2 day.

Ocean AVENGER CNC Beam Lines can be programmed in one of two ways:

1. At the machine, manually enter the profiles to be drilled.

2. Directly Import of the data to the CNC beam line directly from your CNC steel detailing files.

1. MANUALLY PROGRAMMING YOUR OCEAN AVENGER CNC BEAM DRILL LINE

A. MANUAL DETAILING (FROM A PAPER DRAWING)

The Ocean AVENGER can be programmed manually at the machine or in the office using the supplied Peddimat software. This software comes included with the AVENGER and can be installed on as many PCs in your office as you choose — this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the Ocean AVENGER and all Peddinghaus CNC fabricating machinery.

Peddimat is incredibly simple and intuitive, and takes less than an hour to learn, even if you have never worked on a computer in your life.

We always train your operator how to run the machine using Peddimat as you are often going to have the situation where a customer arrives with a couple of pieces of steel that need holes or layout marks and you want to be able to produce them quickly without bothering your detailing staff who might be busy on a larger job.

2. IMPORTING STEEL DETAILING FILES DIRECTLY TO YOUR OCEAN AVENGER CNC BEAM LINE

B. IMPORTING FILES DIRECTLY FROM YOUR STEEL DETAILING SOFTWARE

It is obviously preferable to import files directly from your steel detailing software because it eliminates an unnecessary step and also eliminates possible incorrect data capture. There are two separate and distinct camps in this respect:

1. 3-D Modeling Camp

Software that falls in this camp includes X-Steel, SDS/2, Tekla Structures, StruCAD, DetailCAD, BOCAD, SteelCAD, ProSteel 3-D etc. All these 3-D modeling programs export the DSTV file that is seamlessly imported into the AVENGER.

Your detailer will then supply you a DWG / PLT / PDF file that you will use to print or plot your drawings. He will also supply you with the NC or NC1 files that you will import directly into your machine. The DSTV-Import function is standard on the Ocean AVENGER.

2. AutoCAD Camp

AutoCAD is and architectural software and works well for exporting flat 2-D pieces to plate processing machines. Where it falls short is in its ability to export files for 3-D shapes like beams, channel, angles etc. AutoCAD exports both DWG files and DXF files which are perfect for plates.

The Ocean AVENGER can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

Once you have created a DXF IMPORT COMPLIANT AutoCAD file, you then import it via the DXF-Import Utility (optional purchase)

The Ocean Avenger CNC Drill Line is typically sold with the following options:

The Ocean Flipper Beam Rotator is a simple and unique material handling component, that was originally designed to fit within the material support tables of the Ocean Avenger and other single-spindle drill lines, or other types of steel processing equipment where turning and positioning of profiles is required.

The Flipper reduces the demand on the overhead cranes, leaving this valuable resource free to move other items while the Flipper rotates beams on the Avenger. >>MORE ABOUT THE FLIPPER

The Ocean Rejuvenator Drill Grinder is the industry standard for sharpening twist drill bits. Ocean Machinery’s Penetrator twist drill bits have a standard length of 6″ (150mm) of fluted (working) length. When drilling typical 1/2″ (12mm) thickness, most drill bits will give in excess of 500 holes per sharpening, and when using the Ocean Rejuvenator to sharpen the drills, most customers achieve somewhere between 100 to 200 resharpenings. This means that a standard Penetrator can give you around 50,000 to 100,000 holes per drill

The Ocean Rejuvenator Drill Grinder is the industry standard for sharpening twist drill bits. Ocean Machinery’s Penetrator twist drill bits have a standard length of 6″ (150mm) of fluted (working) length. When drilling typical 1/2″ (12mm) thickness, most drill bits will give in excess of 500 holes per sharpening, and when using the Ocean Rejuvenator to sharpen the drills, most customers achieve somewhere between 100 to 200 resharpenings. This means that a standard Penetrator can give you around 50,000 to 100,000 holes per drill

At Ocean Machinery we are committed to providing you as many options as possible with regard to drilling with your Ocean Avenger or any other CNC Beam Drill Line.

We stock a full range of drill bits and insert drills from several manufacturers, including

If you are not sure whether to use Twist Drill bits or Insert Drill Bits on your Drill Line, please take a look at the comparison of Insert Drill Bits vs. Twist Drill Bits below.

The Ocean Penetrator Cobalt Drill Bits arrive from the factory pre-sharpened to 175 degrees with a split point. We stock 7/16″ thru 2″ diameter drills, and extended length drills are available 9/16″ thru 1-1/16″. They feature:

Prior to the introduction of the Ocean Penetrators, the Nachi Cobalt twist drill was possibly the most well known drill bit on the market. This bit has proven itself in thousands of fabrication shops around the world, and features:

Insert Drill bits are also known as Spade Drill bits. Insert Drill Bits are well known to fabricators and offer the advantage of eliminating the need for a drill sharpening machine. They feature:

We at Ocean Machinery are often asked by our customers what drill bits should they use – twist drill bits or insert bits? Our number one agenda is to ensure that our customers pursue the lowest cost per hole drilled, as this will make them more competitive and profitable. However it is important that they fully understand their options, Insert Drill Bit (Spade Drill Bit ) Advantages

| Insert Drill Bits | Twist Drill Bits |

| Advantages | |

| Savings – You avoid having to spend $10,000 on a drill grinder. | Savings – You do not need to grind the exit of the hole – save on non value added activity. |

| Convenience – They always have a perfectly ground structural point. | Savings – Twist drill bits cost less than 1/10th the cost of insert drill bits – see worked costing example below. |

| Convenience – Nobody has to learn the art of sharpening drill bits. | Convenience – It only takes a couple of hours to train an operator to be able to sharpen drill bits. |

| Simplicity – They can just be discarded when dull and they are cheap to replace – around $40 every 800 – 1000 holes. | Savings and Convenience – you can purchase twist drill bits from any vendor – you are not locked into a particular supplier. |

| Savings – No matter how badly you dull a drill point it can always be resharpened – in some cases you can also resharpen a broken drill bit | |

| Disadvantages | |

| Cost – Insert Drill require holders for each drill size and you require at least two holders of each size. | Inconvenience – You need to train an operator how to sharpen drills. |

| Cost – Insert bits definitely leave a burr on the exit of the hole, especially on lighter profiles and the fabricator must spend money on labor and consumables to grind the exit of the hole. | |

| Cost – If an insert breaks, the tool holder will be damaged and will have to be replaced – replacing tool holders is expensive. | Cost – you have to purchase a $10,000 drill grinder. |

| Cost – If the Torx head holding the insert is stripped you have to replace the tool holder – replacing tool holders is expensive. | |

| Cost – see worked costing example below. | |

Let’s compare Twist Drill Bits and Insert Drill bits in the real life fabrication situation. We will just look at one example – 13/16″ (22mm), which is typically the most commonly drilled hole diameter.

Lets First Look At The Cost Of Using Twist Drill Bits That Need To Be Resharpened

A. Cost to drill 120,000 holes is $376 consumable cost, plus the $10,000 capital of the sharpener which gets amortized over the life of the machine – There are many Ocean Rejuvenators grinders in fabrication shops that are in excess of 10 years old that have repaid their owners many times over.

Now Lets Look At The Cost Of Using Insert Drill Bits

B. Cost to drill 120,000 holes is $396 + $5,400 = $5,796 (consumable cost)

The consumable cost is 15 TIMES more expensive using insert drill bits

We believe that for now, based on current pricing from the various suppliers, the customer is better off with good quality Ocean Penetrator twist drill bits and a good quality sharpener.

Of course, training an operator to sharpen drill bits properly is important, and we do a thorough job during the installation of the Avenger. We have trained hundreds of operators who totally get it and are able to resharpen bits in less than a couple of minutes.

* Pricing comparison during Summer of 2014, drill and inserts prices are subject to change without notice. Consult Ocean Machinery for current pricing information. *

The Ocean Avenger is supplied with a full set of three Morse taper reducers 1 x Mt4-MT3, 1 x MT4-MT2, and 1 x MT3-MT2. However it is advised to have additional reducers on hand to make tool changes faster and more productive

Ocean offers two sizes of positioning magnets to assist with drilling base plates and flat bar. Magnets are available in 8×8″ (200x200mm) and 4×4″ (100x100mm)

Ocean Machinery’s magnetic brush and broom help with the removal of chips from the machine and for sweeping up chips from the floor

These drop-in serrated grippers help to secure base plates, flat bar, angle and other profiles that might have rounded edges that want to push away from the datum line

This Morse Taper chuck adaptor allows you to use standard parallel shank drill bits when drilling smaller diameters. It allows a maximum drill diameter of ?” (12mm) and a minimum diameter of 3/64″ (1mm)

Over the past decade the UNIST MQL lubricant system has become the dominant coolant system in the USA, and has become standard equipment on the Aveger FORTY, Avenger PLUS and Clipper. This minimum quantity lubricant is an oil based coolant that promotes longer tool life. It is non toxic.

The Ocean Avenger is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Avenger. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

The Ocean Avenger is built exclusively for Ocean Machinery by Peddinghaus. Peddinghaus handles the installation, warranty and service work on the Ocean Avenger. And while Peddinghaus is the service provider, Ocean Machinery is always there to get involved should the need arise.

Peddinghaus’s commitment to service and support is legendary and is the gold standard in the industry. Peddinghaus offers a global team of customer support representatives that are always available at the Peddinghaus 24 hour customer support center. Through state-of-the-art remote diagnostic software, readily available local field support, and the industry leading warranty, support from Peddinghaus is only a call or a click away.

To service our global clientele, Peddinghaus proudly provides our partners with 24 hour technical support. Peddinghaus’ inside service staff have years of experience in the field, assembly, or factory checkout which provides them with hands-on experience with most machines. At Peddinghaus their service staff is not only available when you need them, but they maintain superior knowledge to solve questions as they arise.

Although 90% of support issues can be resolved by Peddinghaus’ 24 Hour Tech Support center, an expansive network of 50+ Peddinghaus field service personnel are stationed throughout North and South America, Europe, Africa, Asia, Russia, the Middle East and Australia/New Zealand.

Peddinghaus inside service technicians often don’t need to be at your machine to solve a problem you may have. A common internet connection is all that is needed for the Peddinghaus technician to operate your control as if he was standing with you at the machine. The Powerful Windows® based Siemens control used on Peddinghaus equipment allows for this capability, and provides superior diagnostics via Windows® based platform.

Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Peddinghaus machines are shipped with high definition web cameras and software; allowing Peddinghaus employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.

| The Peddinghaus Technical Support Office is open from 7am to 7pm Central Time, and is always ready to answer your questions, no matter how simple or complicated. | The office hours for Ocean Machinery are 8am to 5pm Eastern Time, and we are intimately familiar with all aspects of the machine and we welcome your technical support calls |

| Call Peddinghaus Technical Service at (815) 937-3800Toll Free (800) 786-2448 | Call Ocean Machinery Technical Service at (800) 286-3624 |