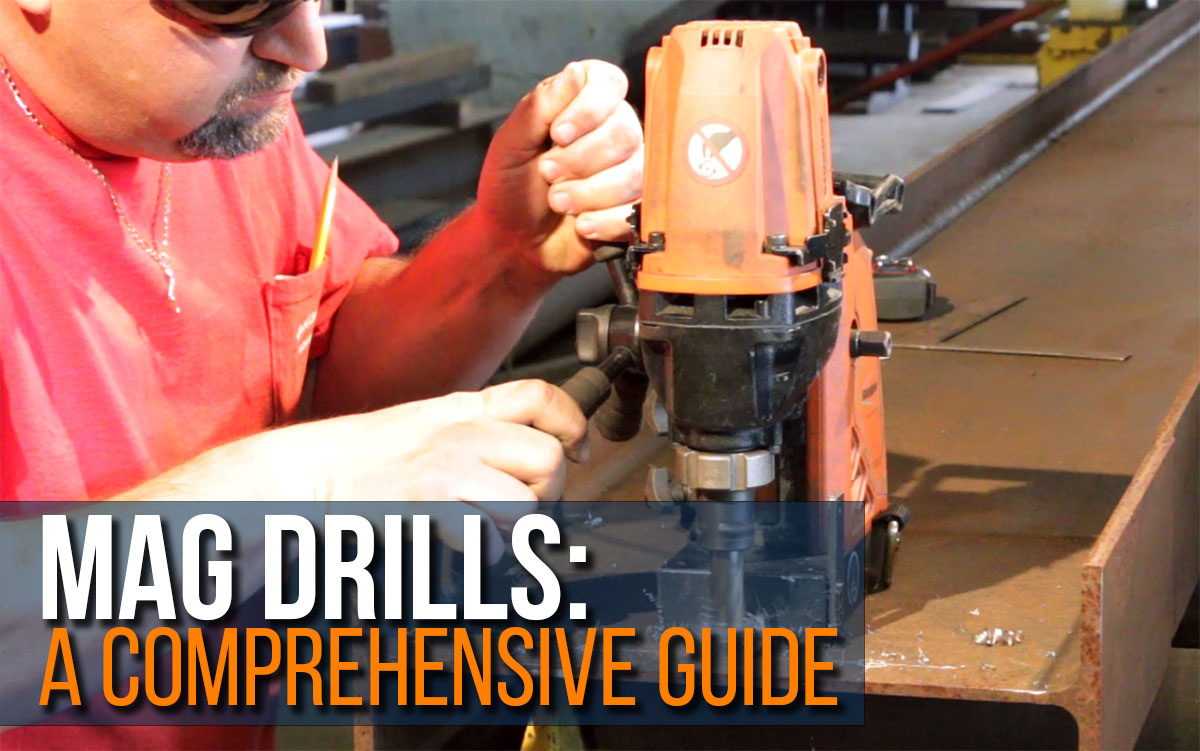

When it comes to metalworking and construction, magnetic drills have become an essential tool for many professionals. Known for their ability to drill through tough materials while remaining stable, they offer a level of precision that handheld drills simply can’t match. However, not all magnetic drills are created equal. In this post, we’ll explore the key differences among various types of mag drills, helping you choose the right one for your needs.

A magnetic drill, often referred to as a mag drill, is a portable drilling machine that uses an electromagnetic base to adhere to ferromagnetic surfaces. This feature allows for stable drilling, particularly on vertical or overhead surfaces, making it an invaluable tool for construction and metal fabrication.

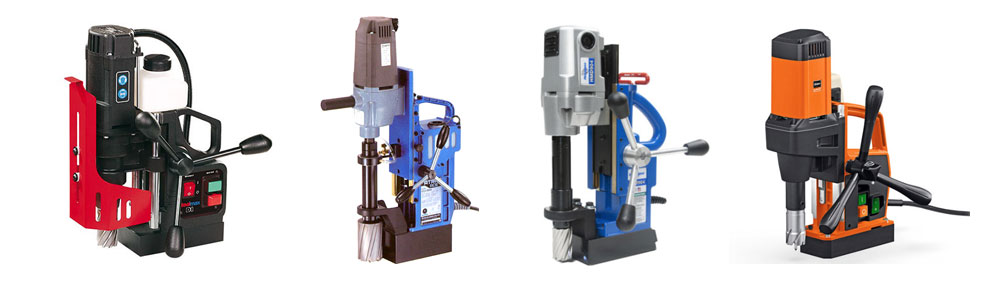

Manual Feed: The most common mag drills are manual feed. These require the operator to feed and retract the cutter through the metal manually. Manual feed options such as the Fein JME Short Slugger II and the Hougen HMD 904 are very popular with fabricators.

Automatic Feed: These drills feed and return to the start position automatically, enabling the operator to press START and run several automatic mag drills at one time! A great example of this is the Nitto Kohki QA-5000 which features a 2″ x 2″ hole capacity.

Core Bits vs. Twist Bits: Mag drills primarily use two types of bits: core bits and twist bits. Core bits are designed for large holes and typically remove a cylindrical core of material. They are ideal for heavy-duty applications. Twist bits, on the other hand, are used for smaller holes and can provide more versatility in drilling. >>LEARN MORE

Electric vs. Pneumatic: Mag drills can be powered by electricity or compressed air. Electric models are common and often come with variable speed settings, allowing for more control over the drilling process. Pneumatic models like the Steelmax D1 Air ATEX or the Steelmax D175 ATEX, are beneficial in environments where electricity isn’t readily available such as underwater and provide high torque.

Motor Power: The wattage or horsepower of the motor can greatly affect performance. Higher-powered drills can handle tougher materials and larger diameter bits, while lower-powered models may be more suitable for lighter applications.

Holding Force: The strength of the magnetic base is crucial. A stronger hold allows for drilling on vertical and overhead surfaces without risk of slipping. Look for drills with high holding forces, especially if you’re working with thick materials or in challenging positions.

Magnet Type: Some drills use permanent magnets, while others utilize electro-magnets. Electro-magnets can be turned off for easy repositioning but require a power source. Permanent magnets provide a constant hold but may be more difficult to adjust.

Size and Weight: Mag drills come in various sizes, affecting their portability. Lighter models are easier to transport and maneuver, while heavier models may offer more stability during use. Consider your work environment and the typical materials you’ll be drilling into when choosing a model.

Variable Speed Control: Many modern mag drills come with variable speed control, allowing users to adjust the drilling speed based on material type and hole size. This feature enhances precision and reduces the risk of damage.

Depth Stop and Feed System: Some models include a depth stop feature to ensure consistent hole depths. A built-in feed system can also streamline the drilling process by allowing for smooth, controlled drilling without requiring excessive manual effort.

Additional Accessories: Consider whether the drill can accommodate various attachments and accessories, such as coolant systems for cutting metal, which can prolong bit life and improve performance. Call (800) 286-3624 for information and pricing on accessories.

Mag drills can vary significantly in price, influenced by factors such as brand, features, and specifications. While it might be tempting to go for the cheapest option, investing in a high-quality mag drill often pays off in terms of durability and performance, especially for heavy-duty applications. Our Team is dedicated to providing the right solution for your job, give us a call at (800) 286-3624.

Choosing the right magnetic drill requires careful consideration of your specific needs and the types of materials you’ll be working with. By understanding the differences in drill bits, motor types, magnetic base strength, weight, features, and price, you can make an informed decision that enhances your workflow and ensures precision in your projects. Whether you’re a seasoned professional or a DIY enthusiast, the right mag drill can make all the difference in your metalworking endeavors. Happy drilling!