The Ocean Avenger PLUS is a versatile CNC drill line designed for fabricators and manufacturers requiring advanced processing capabilities. It handles a wide range of materials and profiles, offering drilling, milling, tapping, slotting, and more with high precision and efficiency. Its compact footprint, heavy-duty design, and automation features such as an 8-position tool changer significantly enhance productivity in various industries.

The Avenger PLUS is designed for fabricators and manufacturers whose requirements exceed those of the standard single spindle drill line. It aims to serve a broader range of industries by offering enhanced capabilities beyond drilling holes and adding layout marks.

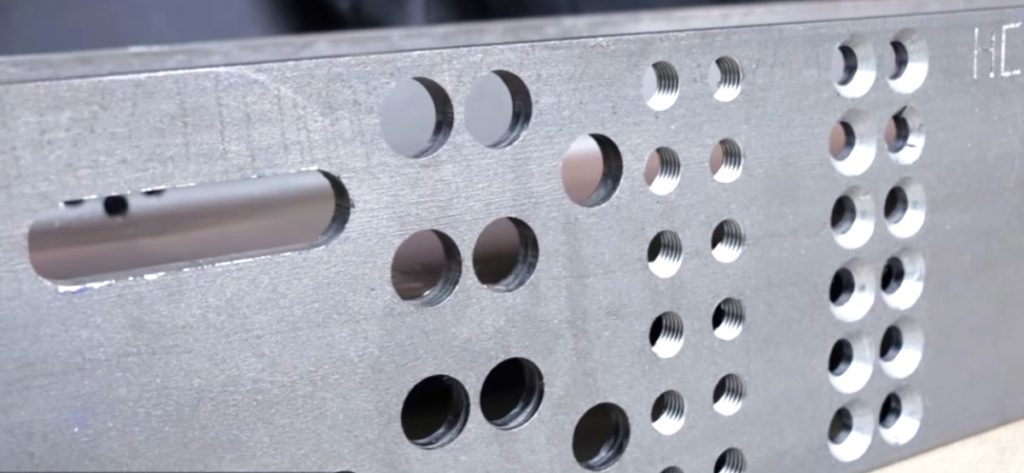

Together with our manufacturing partner Peddinghaus, Ocean Machinery designed the Avenger PLUS CNC drill line to perform a comprehensive set of operations, including:

This extensive functionality makes the Avenger PLUS suitable for a wide array of fabrication and manufacturing tasks.

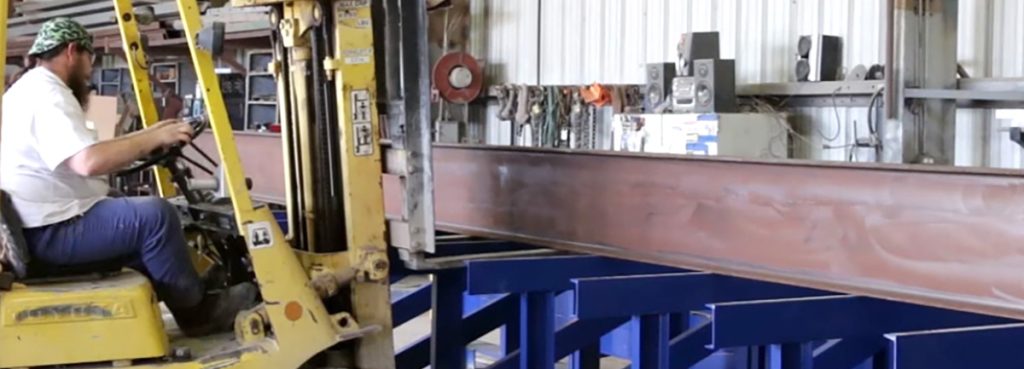

To accommodate long and tall profiles, the Avenger PLUS features an entirely new heavy-duty table and a more substantial drilling platform. The machine table is designed for easy loading and unloading using overhead cranes or forklifts.

Despite its robust construction, the machine maintains a small footprint, making it suitable for even the smallest shops. The Avenger Plus is available in lengths ranging from 20 feet to over 100 feet.

Once a part is clamped to the table, a laser detects the left-hand end of the profile and sets a zero X reference point. An encoder in the clamp provides continuous measurement in the Y direction, allowing measurements from the table upward or the clamp downward.

When processing beam flanges, a web sensor locates the actual web centerline using profile dimensions from a comprehensive library of shapes. This library includes all standard worldwide shapes, and custom profiles can be easily added.

The Avenger Plus features a through-the-tool minimum quantity lubrication system that ensures fast machining and extends tool life. It is compatible with both regular High-Speed Steel (HSS) tooling and carbide tooling.

The machine uses a hydraulic clamp to secure the profile to the table bed. Additionally, a sub-X axis allows the entire rigid machine, including the spindle, to move laterally under the clamp. This design enables:

The solid unit movement provides unparalleled rigidity, allowing faster milling and drilling across all profile sizes and thicknesses.

For lighter profiles, parts can be rotated by hand to machine additional surfaces. For larger profiles, overhead cranes, forklifts, or optional Ocean Flipper facilitate fast rotation.

The enhanced functionality of the Ocean Avenger PLUS has attracted a new class of customers producing a diverse range of products, including:

The Ocean Avenger PLUS Multi-Function Machine represents a major advancement in CNC fabrication technology. Its versatility, precision, and efficiency make it an invaluable asset for fabricators and manufacturers across numerous industries. With its compact design and extensive capabilities, the Avenger PLUS is redefining productivity and quality in the structural steel industry.

For more information, contact Ocean Machinery at 1-800-286-3624

or submit an Information Request Form.