Description

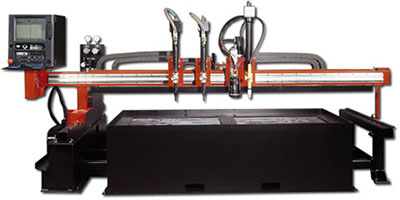

The ACS Fabmaster-II Plasma Cutting Table is designed for the Job Shop, Structural Steel Fabricator, Steel Service Center and Miscellaneous Steel Fabricator. The ACS Fabmaster-II is one of the most versatile cutting machine platforms, allowing the customer to add Conventional Plasma, Precision Plasma, Plasma Marking, Scribing and Multiple Oxy-fuel Cutting Heads.

The ACS Fabmaster-II is designed to cut out geometric shapes and parametrically programmed Blow Pipe Fittings or Structural Steel Base Plates. The parts are programmed in the office using Profile Master PM-2000 Fab-CAM (Computer Aided Manufacturing) software; the parts are then nested on a sheet of metal to minimize material waste and are then cut out at high speed using a Plasma Torch or an Oxy-fuel Torch. Parts can also be imported from AutoCad, X-Steel, SDS or other popular programming systems.

- The Fabmaster-II is offered in three cutting widths: 5′, 6′ and 8′, and four cutting lengths: 10′, 12′, 20′ and 24′.

- As a standard feature, the Fabmaster-II includes the Promotion Color Graphic Control, with the Burny Phantom available as an option.

- The Fabmaster-II can be equipped with a Hypertherm, Kaliburn or Thermal Dynamics Conventional Plasma or Hypertherm HPR Precision Plasma, Kaliburn Spirit or ProLine Precision Plasma or Thermal Dynamics Ultra Cut Precision Plasma.

- Several models of Automatic Torch Height Control (THC) are available depending on the plasma.

- Up to three Oxy-fuel heads can be added.

- Optional Water Tables or Downdraft Cutting Tables are available.

- Onsite installation and training is included with every Fabmaster-II.

Call the Ocean Machinery sales team TODAY at (954) 956-3131 or Toll Free 1 (800) 286-3624 or fill out our online info request form for more information on ACS Fabmaster-II Plasma Cutting Table.